Analog computers have long been instrumental in control systems, offering unique advantages that make them invaluable for controlling and regulating various processes. Control systems play a critical role in industries such as manufacturing, robotics, aerospace, and automation, where precise control and real-time response are essential. In this article, we will explore the advantages of analog computers in control systems and understand why they continue to be relevant in this domain.

Control systems are designed to manage and regulate the behavior of dynamic processes. Analog computers offer specific advantages that make them highly suitable for control systems, complementing the capabilities of digital systems. By leveraging the continuous nature of analog computation, analog computers excel in providing precise control, real-time response, and stability in control systems.

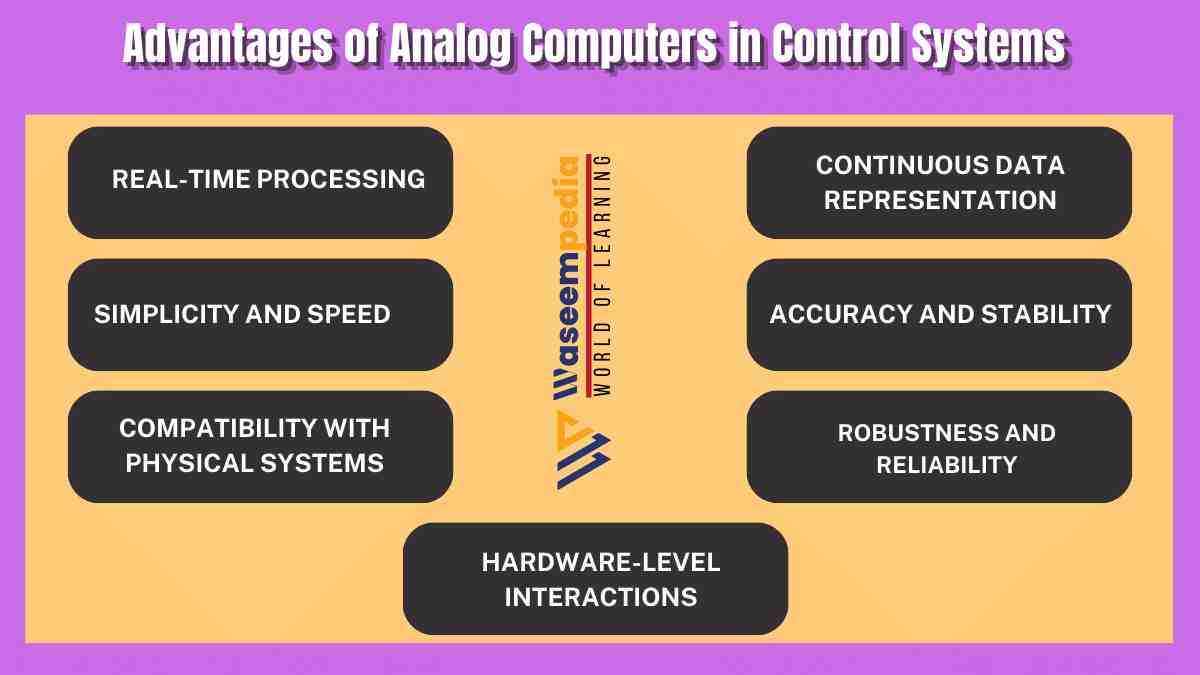

Analog computers offer significant advantages in control systems, providing real-time processing, continuous data representation, simplicity, speed, accuracy, stability, compatibility with physical systems, robustness, reliability, and hardware-level interactions.

Their ability to process continuous signals and directly model real-world phenomena makes them ideal for control applications where precise control, real-time response, and stability are crucial. While digital control systems have gained popularity, analog computers continue to provide unique benefits, contributing to the advancement and effectiveness of control systems in various industries.

What is Analog Computers?

Analog computers process information using continuous physical quantities, such as voltages or currents, to represent and manipulate data. Unlike digital computers that operate on discrete values, analog computers can directly model real-world phenomena with high accuracy. This characteristic makes analog computers well-suited for control systems, where continuous feedback and control signals are crucial.

7 Advantages of Analog Computers in Control Systems

7 Advantages of Analog Computers in Control Systems are as following.

1. Real-Time Processing

Real-time processing is a vital requirement in control systems, as they need to respond to changes in the controlled process in real-time. Analog computers excel in this aspect, as they can process continuous data streams with minimal delay.

By immediately analyzing incoming data and providing instantaneous control signals, analog computers enable real-time monitoring and adjustment of the controlled system. This capability ensures precise control and timely responses.

2. Continuous Data Representation

Analog computers utilize continuous data representation, allowing them to capture and manipulate the fine-grained details of a controlled process. In control systems, where accurate and precise control is crucial, analog computers shine.

By working with continuous signals, analog computers can maintain the fidelity of the control process without the need for discretization. This continuous representation leads to smoother control actions and enhances the overall performance of the control system.

3. Simplicity and Speed

Analog computers offer simplicity and speed in control systems. The analog nature of computation allows for straightforward and intuitive implementations of control algorithms.

Analog control circuits can often be designed with fewer components and simpler wiring, resulting in reduced complexity and enhanced reliability. Additionally, the inherent speed of analog computation enables fast control actions, contributing to the agility and responsiveness of the control system.

4. Accuracy and Stability

Analog computers provide high levels of accuracy and stability in control systems. Due to the continuous nature of analog signals, control actions can be performed with precision, leading to accurate regulation of the controlled process.

Analog control circuits also exhibit inherent stability characteristics, making them less susceptible to issues like quantization errors or numerical instability. This stability ensures reliable and consistent control performance.

5. Compatibility with Physical Systems

Analog computers are highly compatible with physical systems in control applications. The continuous nature of analog computation allows for seamless integration with physical components and systems. Analog control circuits can directly interface with sensors, actuators, and other physical devices, facilitating accurate measurement and control of the physical process.

This compatibility ensures a tighter coupling between the control system and the controlled process, resulting in more effective and efficient control.

6. Robustness and Reliability

Analog computers are known for their robustness and reliability in control systems. Analog control circuits are often less prone to digital noise or electromagnetic interference, leading to more stable and reliable control operations.

Furthermore, analog components are typically less susceptible to sudden failures or glitches, providing a higher level of system reliability. This robustness and reliability make analog computers suitable for critical control applications where consistent and dependable control is essential.

7. Hardware-Level Interactions

Analog computers enable direct hardware-level interactions in control systems. Engineers can design analog control circuits that interface directly with physical components, allowing for real-time monitoring and control of the controlled process.

This hardware-level interaction provides a more direct and immediate influence on the physical system, enabling precise adjustments and facilitating optimal control. Such direct interactions contribute to the efficiency and effectiveness of analog control systems.

Related FAQ’s

How do analog computers differ from digital computers in control systems?

Analog computers process continuous data and directly model real-world phenomena, while digital computers operate on discrete values and rely on algorithms for control actions.

What advantages do analog computers offer in control systems?

Analog computers excel in real-time processing, continuous data representation, simplicity, speed, accuracy, stability, compatibility with physical systems, robustness, reliability, and hardware-level interactions.

Why is real-time processing important in control systems?

Real-time processing enables control systems to respond to changes in the controlled process immediately, ensuring precise control and timely adjustments.

How do analog computers ensure accuracy and stability in control systems?

Analog computers process continuous signals, allowing for accurate control actions and inherent stability in control circuits.

Why are hardware-level interactions valuable in control systems?

Hardware-level interactions enable direct control and monitoring of physical components, resulting in precise adjustments and optimal control performance.