Artificial Intelligence (AI) has changed how manufacturing and automation work, bringing lots of advantages to businesses in the industry. It helps factories become more efficient, productive, and make better products. AI technology is like a makeover for manufacturing processes.

By using AI and its cool abilities, manufacturers can stay competitive, save money, and produce top-quality products to meet what customers want. AI is like a smart helper that makes manufacturing smarter and better!

In this article we will read the Advantages of Artificial Intelligence in Manufacturing and Automation in detail.

Artificial Intelligence in Manufacturing

Artificial Intelligence (AI) means creating smart machines that can do tasks just like humans. In manufacturing and automation, AI is used to make things work better and faster. It helps improve how things are done and makes everything run smoothly and efficiently.

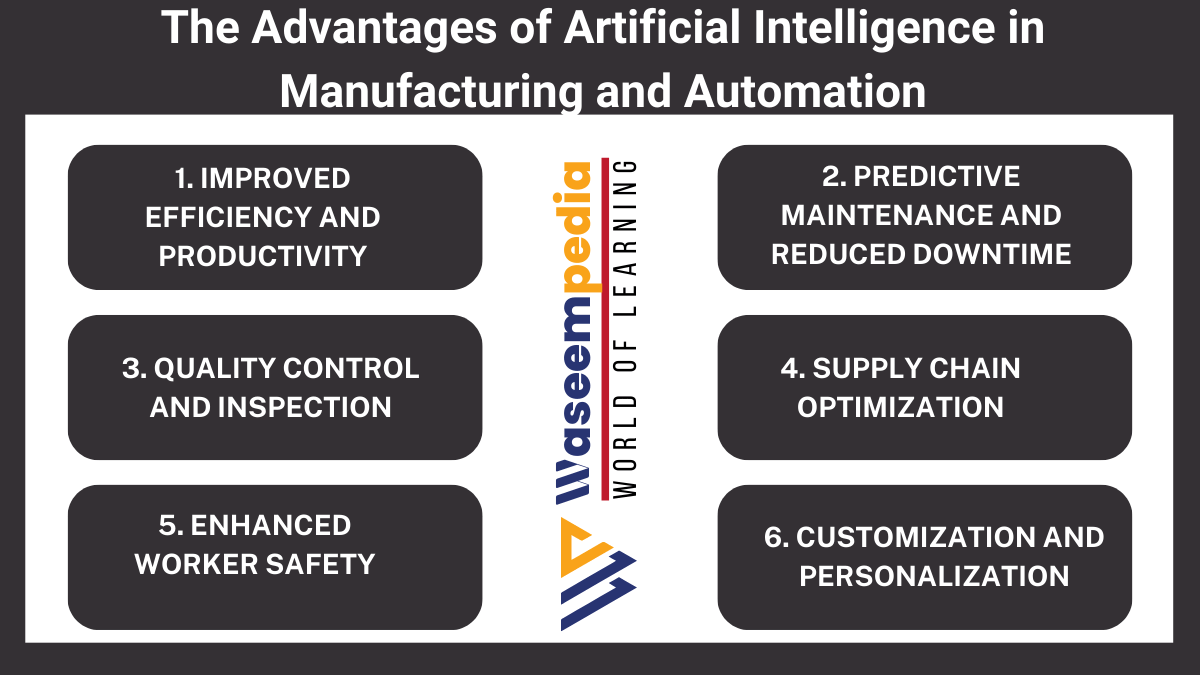

9 Advantages of Artificial Intelligence in Manufacturing

9 Advantages of Artificial Intelligence in Manufacturing are given blew.

1. Improved Efficiency and Productivity

AI in manufacturing helps things get done faster and better. Smart AI systems can quickly analyze lots of data, so manufacturers can make smart decisions. It also automates repetitive tasks and improves how things are done, which means fewer mistakes and smoother operations.

2. Predictive Maintenance and Reduced Downtime

AI can predict when machines need maintenance, so they don’t break unexpectedly. By checking machines in real-time, AI can find problems before they become big issues. This way, manufacturers can plan maintenance and avoid unexpected stops in production.

3. Quality Control and Inspection

In manufacturing, making sure products are high quality is crucial. AI uses smart technology to check for any problems or defects in products. It looks at the things being made using cameras and special algorithms. This helps manufacturers catch mistakes early and avoid making faulty goods.

4. Supply Chain Optimization

AI helps manufacturers manage their supplies and products efficiently. It looks at lots of information like sales forecasts and customer needs. By using this data, manufacturers can plan better and deliver products on time without running out.

5. Enhanced Worker Safety

AI is also good for keeping workers safe in factories. It can use robots to do dangerous tasks, reducing the chances of accidents. AI can even watch the workplace for any safety risks and give alerts to avoid problems.

6. Customization and Personalization

AI helps make products just how customers want them. It collects data about what customers like and uses that information to create personalized items. This way, manufacturers can make products that customers will love.

7. Waste Reduction and Sustainability

AI is great for helping the environment by using resources wisely. It looks at data to find ways to reduce waste and save energy. This makes manufacturing more sustainable and helps take care of the planet.

8. Cost Savings and Return on Investment (ROI)

Using AI in manufacturing can save money and give good results. It makes things more efficient, reduces costs, and boosts productivity. Manufacturers can earn back the money they invest in AI because it helps them work better in the long run.

9. Future Trends and Innovations

The future of AI in manufacturing is exciting! There are cool new ideas like connecting AI with smart devices and using advanced robots. It can make factories even smarter and help them make things even faster and better.